There are two basic types of metal additive manufacturing available. There is Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). Buchanan Sales offers primarily EBM but can provide DMLS on a selective, case-by-case, basis.

The benefits to both processes are:

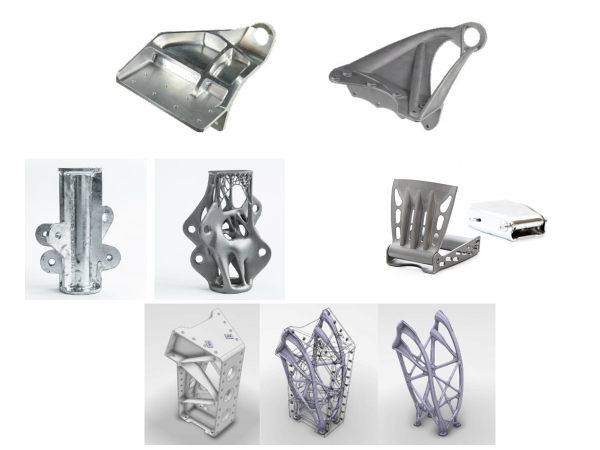

- Accurately Forms Complex geometries that are not available in traditional metal manufacturing methods

- Faster turnaround to market – reduced lead times

- Parts are denser than Investment Cast parts

- Can print in internal passages that could not be machined in

- Reduced weight of parts

- Can possibly combine previously assembled components into one part

- Increased design flexibility

- Reduced tooling

Both Processes build components directly from 3D CAD Model:

- Utilize powdered metals

- Built layer by layer

- DMLS uses 20 micron layers with fine powders

- EBM uses thicker layers with coarser less expensive powder

- Both processes use a beam (laser or electron) to melt and build the parts

New materials continue to be developed for this process; current materials include but are not limited to:

- Stainless Steels (15-5, 17-4, 304 and 316)

- Aluminum

- Maraging Steel

- Titanium

- Tantalum/Molybdenum

- Copper

- Inconel

- Cobalt Chrome

Additive manufacturing is most commonly used in the prototyping process, but can be utilized for other production needs depending on the component. Production volumes, based on the part, are also possible.

We represent suppliers from both domestic and international manufacturers. Buchanan Sales’ technical sales representatives will match your product to the best process and supplier.